High-resolution In-situ Measurement of Nanoscale Friction and Wear

Research Background

Material systems exhibiting superlubric characteristics (extremely low friction and/or near-zero wear), such as van der Waals (vdW) heterostructures and hard alloy interfaces/coatings, have recently garnered significant attention in both the scientific and industrial communities. These systems hold tremendous potential for applications in fields like Micro-Electro-Mechanical Systems (MEMS), aerospace, and advanced manufacturing. Van der Waals heterostructures, as emerging solid lubricants, offer promising solutions for friction and wear issues in the micro/nanoscale moving parts of MEMS devices. Similarly, hard alloy interfaces and coatings with exceptional wear resistance are poised for significant applications in high-demand scenarios such as aerospace and high-precision manufacturing.

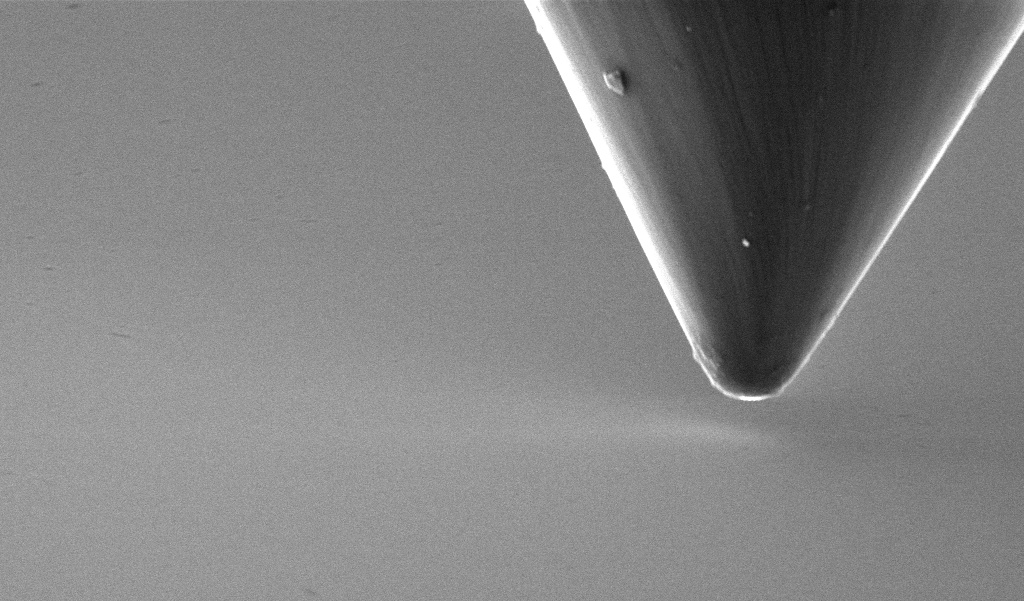

However, the superlubricity and wear-resistant performance of these systems are influenced by a complex array of factors and external conditions. The underlying mechanisms of interfacial wear and the factors affecting them are not yet fully understood, which severely hampers the control and optimization of these material systems' performance. A major challenge in studying such interfacial wear mechanisms is the lack of high-resolution in-situ measurement techniques. This limitation prevents real-time observation and quantitative analysis of interfacial friction and wear processes at nanoscales, thereby impeding a deeper understanding and advancement of these promising materials.

Material systems exhibiting superlubric characteristics (extremely low friction and/or near-zero wear), such as van der Waals (vdW) heterostructures and hard alloy interfaces/coatings, have recently garnered significant attention in both the scientific and industrial communities. These systems hold tremendous potential for applications in fields like Micro-Electro-Mechanical Systems (MEMS), aerospace, and advanced manufacturing. Van der Waals heterostructures, as emerging solid lubricants, offer promising solutions for friction and wear issues in the micro/nanoscale moving parts of MEMS devices. Similarly, hard alloy interfaces and coatings with exceptional wear resistance are poised for significant applications in high-demand scenarios such as aerospace and high-precision manufacturing.

However, the superlubricity and wear-resistant performance of these systems are influenced by a complex array of factors and external conditions. The underlying mechanisms of interfacial wear and the factors affecting them are not yet fully understood, which severely hampers the control and optimization of these material systems' performance. A major challenge in studying such interfacial wear mechanisms is the lack of high-resolution in-situ measurement techniques. This limitation prevents real-time observation and quantitative analysis of interfacial friction and wear processes at nanoscales, thereby impeding a deeper understanding and advancement of these promising materials.

Research Content

i)Develop high-resolution in-situ methods for measuring friction and wear;

ii)Conduct precise in-situ measurements and characterization of the friction and wear properties of hard alloy interfaces/coatings and vdW interfaces;

iii)Design materials/interfaces and coatings with ultra-low friction and superior wear resistance.

i)Develop high-resolution in-situ methods for measuring friction and wear;

ii)Conduct precise in-situ measurements and characterization of the friction and wear properties of hard alloy interfaces/coatings and vdW interfaces;

iii)Design materials/interfaces and coatings with ultra-low friction and superior wear resistance.